Fueling the Future:

From Market Need to Product Strategy

Background and Motivation:

The aviation sector is a major contributor to global climate change, accounting for about 2–3% of global CO2 emissions and 12% of transport emissions. As public and regulatory pressure has grown, airlines and international organizations have pledged to reduce emissions.

Governments worldwide are implementing policies to accelerate SAF adoption by having regulatory mandates and incentives.

Strategic landscape

I organized a cross‑functional workshop with colleagues from R&D, commercial, regulatory, and supply chain, and began by SWOT analysis around our strategic goal: Increasing global market share in a rapidly evolving, policy‑driven sector.

This collaborative process not only aligned the team on market realities but also generated actionable insights that fed directly into our SAF product roadmap and partnership strategy.

Who are the customers?

Primary customer: Airlines, as majority end users, who are facing 2050 net-zero commitments.

Primary customer: Refiners, as the fuel producers, who are motivated by policy incentives as well as market opportunity.

Secondary customers: Regulators (rule maker), investors (provide capitol), airports (enable the infrastructure).

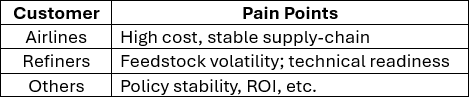

What are the pain points and VoC?

I used a multi‑channel approach to capture the Voice of the Customer (VoC):

Structured interviews with airline sustainability officers and refinery technology managers.

Conversation with customer representatives at relevant conferences.

Analysis from marketing team regarding the public reports.

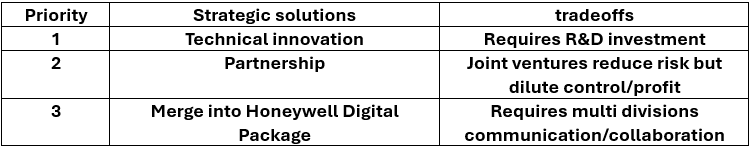

What are the solutions and tradeoffs?

I led a cross‑functional discussion with R&D, supply chain experts and marketing leads to co‑create solution pathways.

By structuring the discussion around customer priorities and quantifying the impact of each option, I helped the team converge on a balanced roadmap: near‑term innovation breakthrough to improve the technical readiness, paired with longer‑term strategic partnerships with airlines and refiners to secure R&D investment and licensing deals.

This approach demonstrated to both customers and internal stakeholders that we were not just reacting to pain points, but systematically weighing tradeoffs to deliver solutions aligned with their most urgent needs.

Built “0 to1” product from Minimum Viable Product (MVP)

I used my technical background, and work with R&D and engineering team to develop a new prototype, via rigorous DOE (design of experiment), that reduced 60% CO2 emission. During the process, I also used my Six Sigma Black Belt knowledge to confirm such differentiation is a truly improvement against the control group (similar to A/B testing).

After communicating with key stakeholders and hearing the feedbacks from the customers, this prototype became the blueprint of our minimum viable product (MVP). So R&D team continued to optimize the product until the delivery.

The final product

Our final product contains several features:

Significantly lower CapEx for customers than competitors.

$14M/year incremental profit to customer due to the technical innovation.

Results in partnership with airlines, such as United Airline, Delta, Japan Airline, ANA.